Nc Code Simulator

Ishqbaaz (Kuch Khidkitod Yaadein) 16th December 2018 Free Watch Online. 79,035 views. Star Plus On Air Serial List. Dance Plus Season 4. Qayamat Ki Raat. Privacy Policy. Star Plus TV include a mix of family dramas, comedy shows, reality, crime or horor shows. Watch all dramas of Star Plus TV channel online with best quality vidoes. You can watch all Star Plus TV old or new drama Follow your favorite tv Channel Star Plus TV or Drama Serials for upcoming videos. Star plus serials online.

G-Code Q'n'dirty toolpath simulator. Paste your g-code in the left-hand window and see the preview of your tool path on the right. The right-hand pane are. Cnc g code simulator free download - G Code Generator OD CNC, Guide to G & M Code CNC Programming, CNC Code for Windows 10, and many more programs.

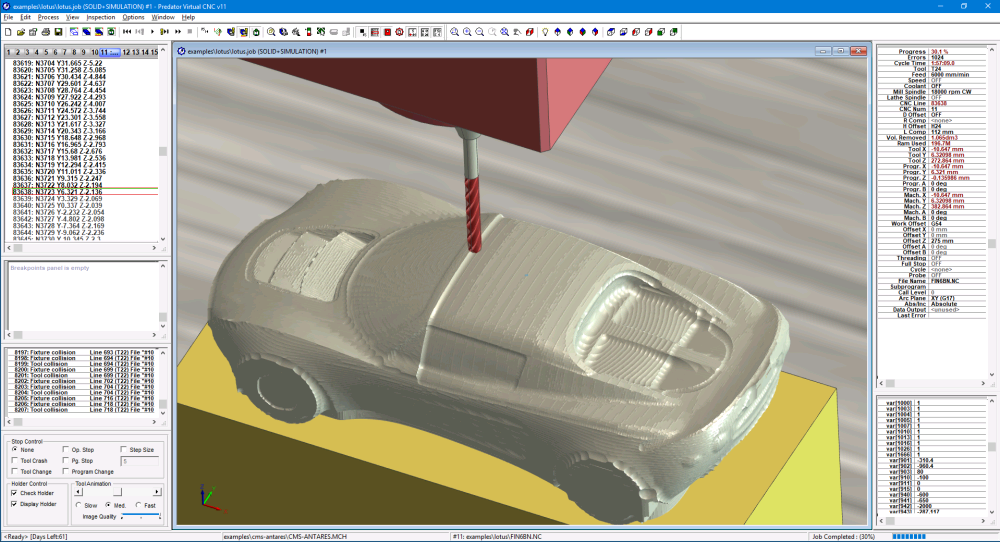

VERICUT software simulates CNC machining so you can be more efficient, more competitive, and more profitable! A machine crash can be very expensive, potentially ruin the machine, and delay your entire manufacturing schedule! But with VERICUT, you can dramatically reduce the chance for error and avoid wasting valuable production time proving-out new programs on the machine. CNC Machine Simulation detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, work pieces, cutting tools, and other user-defined objects. You can set up ‘near-miss zones” around the components to check for close calls, and even detect over-travel errors. VERICUT enables you to perform realistic 3D simulation of entire CNC machines, just like they behave in the shop, with the most accurate collision-detection available.

VERICUT Machine Simulation software supports G-codes and • Multi-axis support for milling, drilling, turning, grinding & EDM machines • Simultaneous mill/turn on different spindles and workpieces • Machines with multiple synchronized CNC controls. • Auxiliary attachments: tail stock, steady rests, part catchers, bar pullers, etc. • Automatic workpiece transfer to pick-off or sub-spindles. Superior Collision Checking VERICUT features the most accurate collision checking available. Rather than just checking points along a path, VERICUT checks along the entire path of travel by sweeping through space. You don’t have to specify a “step size” tolerance that can slow the simulation if too small or miss the collision if too large! CNC Control Emulation & G-code Support VERICUT accurately emulates CNC control logic.

Each control in your shop can be accurately simulated to account for different types of machines, programs, parts, and functions. You get the flexibility to customize controls. Using pull down dialog boxes, G-code characters and numerals are defined in a logical “word/address” format, then configured to call CGTech action macros which simulate control functions. The control logic also supports conditional checks (other codes in the block, current variable values, machine states, etc.) that can alter how the word/address is interpreted.VERICUT includes a library of flexible, easily modified controls from makers such as: • Heidenhain • Fanuc • Mazatrol • Bosch • NumeriPath • Yasnac • General Electric • Siemens • Fadal • Phillips • Allen-Bradley • Cincinnati Milacron • Okuma Today’s NC machine tools process complex NC programs. VERICUT was designed by NC programmers and professionals in NC simulation and verification software. Because of this understanding and expertise, VERICUT is an excellent tool when using multi-axis machines, complex NC code, and/or advanced programming techniques.

VERICUT is designed to support advanced control functions including: • Look-ahead or 3D cutter compensation • Tool tip programming & tool length compensation • Gage length reference point programming • Canned cycles and fixture offsets • Rotary axis pivot points • Variables, subprograms, and macros • Subroutines, looping, and branching log Example VERICUT Machine Configurations (VMCs) are included with the software. These can be used directly in VERICUT or, can be used as a starting point to configure VMC’s of your exact machines. STL and other CAD model formats can be used to represent machine components, or they can be directly modeled in VERICUT. A simple “tree” feature makes it easy to connect the pieces and create the kinematics of the machine. Siemens 840d%SPF8000 $P_UIFR[1] = CTRANS() $P_UIFR[2] = CTRANS(X,22.5, Y,22.5, Z,145) $P_UIFR[3] = CTRANS(X,45+22.5*COS(30), Y,22.5, Z,145+22.5*SIN(-30)):CROT(Y,30):CROT(Z,45) T1 M6 D1 S1559 F1000 M3G0 Z200 $P_IFRAME = CTRANS(X,22.5, Y,22.5, Z,145); M98 PR101 G54 G0 Z250 B30 TRANS G56 M98 PR101 FANUC 30i O20001 WHILE[#2LE270.]DO1 G65 P102 B#2 H#102 S5500 C83 Z.45 F10. G65 P103 B#2 H#102 S5500 C83 Z.45F10.